We are your go-to anodizing shop for low to medium volume, quick turnaround projects.

We offer Type II sulfuric acid anodizing on 6061-T6 and 7075-T6 aluminum.

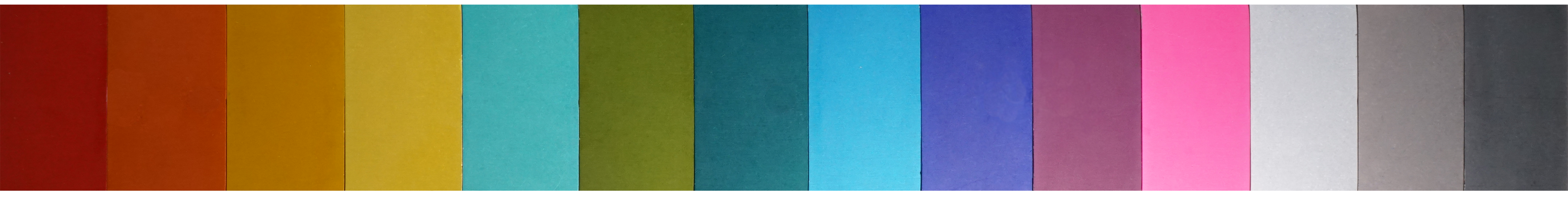

We offer a wide variety of dyes for your perfect color match.

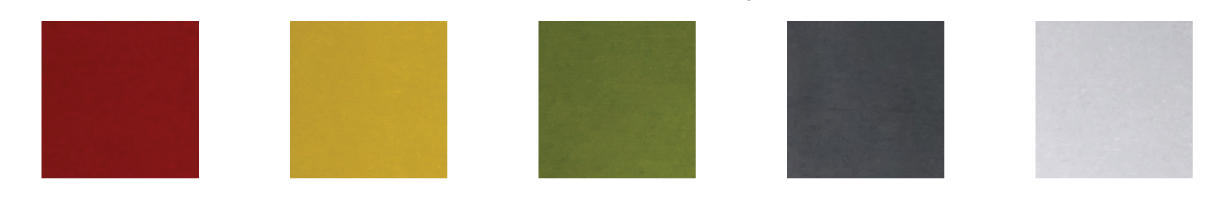

We offer five standard colors that carry no additional costs*

Or we find your perfect match.

*Standard dye colors subject to change.

What is anodizing?

Anodizing is an electrolytic process both for protecting aluminum parts against wear and corrosion and for improving cosmetic appearances.

Why anodizing?

The process improves the part’s mechanical and aesthetic properties, making the part resistant to wear and tear and giving it an attractive finish. The best part about anodizing is that it keeps your aluminum parts safe from corrosion.

What materials can I anodize?

Anodization is key for all grades of aluminum, and can be used for other metals, including titanium, zinc, tantalum and niobium. However, Spark Anodizing is an aluminum only anodizing facility.

What’s the difference between Type II and Type III Anodizing?

Type II anodization is the more standard process of using sulfuric acid, while Type III (hardcoat) involves more demanding conditions to achieve harder coating that’s more resistant to abrasion. Spark Anodizing is a Type II (sulfuric acid) anodizing facility.

What is the process of anodizing?

• Connect the part to an anode

• Submerge the part in acidic electrolyte solution

• Apply a cathode to a metal electrode in the solution

• Positive ions react with negative O2 ions and the surface becomes porous

• This grows a layer of aluminum oxide on the part

• Use corrosion inhibitors or colored dyes for cosmetic purposes

• Seal the nanopores

Is anodizing conductive?

No, anodizing is not conductive. Keep this in consideration when designing your parts. Will anodization wear off? While anodizing leaves a very durable surface finish on your part, an acid wash or general use can wear off anodize eventually.

Will anodizing wear off?

Yes, anodizing can wear away over time due to abrasion, and the color may fade if exposed to sunlight or UV light for a long time.

What are the minimum and maximum part sizes we can anodize?

The maximum size for our facility must not exceed 23".

The minimum size for our facility should not be smaller than .15" (4mm), however we recommend having racking holes at least .15-.30" (4-8mm) in size.

A design review will be conducted to ensure dimensional accuracy.

For more information see our Design Considerations Page

Tell us about your project or request a quote!

Email us at: ano@sparkrandd.com